The WaterHub® At Piedmont Atlanta Hospital

Integrating Water Reuse into an Urban Campus Fabric.

Integrating Water Reuse into an Urban Campus Fabric.

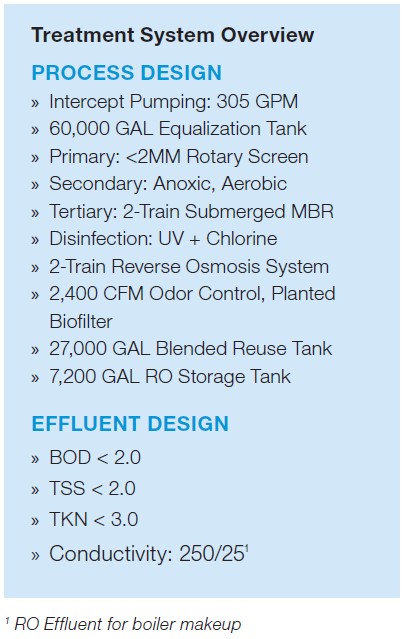

The WaterHub at Piedmont Atlanta Hospital is a campus-scale wastewater reclamation and reuse system. At a hydraulic rating of 250,000 gallons per day, it is designed to intercept nearly all hospital wastewater and eliminate reliance on potable water for campus utility uses. After startup in early 2023, the WaterHub project will reduce the hospital’s water footprint by over 40% and save an estimated 750 million gallons of potable water over the next decade.

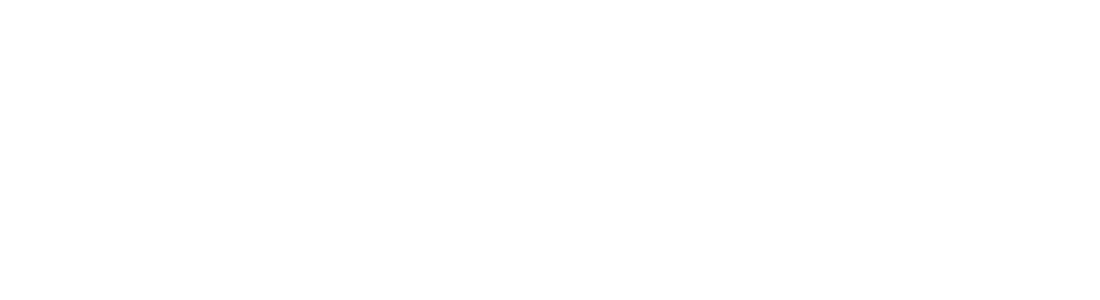

Located in a stressed water supply region, Piedmont Atlanta Hospital was looking to minimize its environmental footprint and improve operational resiliency for its critical-care facility as it expanded operations. In addition to community water conservation, the WaterHub will provide this resiliency through an N+1 water supply and storage in the event of service disruption or drought. With a direct high purity feed to the Central Utility Plant, the WaterHub also provides improved water quality for greater operating efficiency, asset protection, and chemical usage for heating and cooling systems.

The WaterHub is located adjacent to the BeltLine Redevelopment Corridor which will increase foot traffic and provide a new gateway to campus. Because of the increase in foot traffic through this new campus corridor, project design objectives included an improvement to the streetscape to provide an attractive anchor development for this section of campus. The WaterHub features an outdoor hydroponic biofilter, located along the sidewalk, that serves as a performance landscape element. Architecturally, the project mirrors tones and materials used in the broader hospital redevelopment plan.

Project scope involved the construction of three 50-300 gallons per minute lift stations designed to divert and pump wastewater through 1,000 linear feet of force main piping to the treatment facility. A new “purple-pipe” reclaimed water distribution network, totaling 1,200 feet in length, was installed to supply water to four primary non-potable water users on campus.

TECHNOLOGY & DESIGN

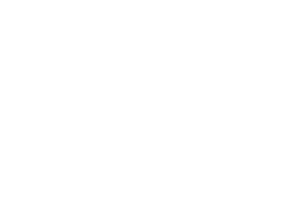

Facility design involves a series of interconnected, below-grade concrete bioreactors which serve as the building’s foundation. The bioreactor tanks include both influent flow equalization and a clean water storage tank. Designated mechanical and operator spaces, including a lab/office, are located directly above the reactors.

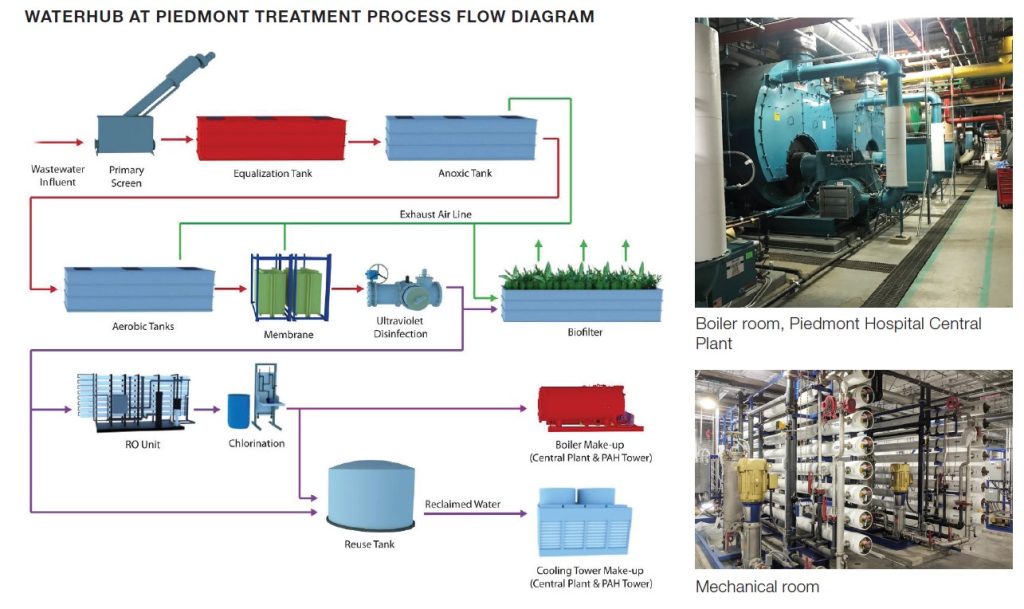

The process design consists of initial solids removal via a rotary drum screen before entering a flow equalization tank. Equalized flows are conveyed to anoxic and aerobic treatment phases for secondary treatment. A submerged membrane bioreactor (MBR) provides tertiary treatment and final removal of suspended solids. Permeate from

the membrane tanks is then disinfected by both ultraviolet light (UV) and an oxidizing biocide (chloramine). The Hydroponic Biofilter is designed to scrub all process air through a natural planted medium. The Biofilter controls any potential odors originating from the facility, while serving as a performance landscaping element.

For final polishing, a portion of the MBR permeate passes through a reverse osmosis (RO) system and is blended with disinfected MBR permeate to create a tailored water quality for cooling tower and boiler uses, respectively. A direct feed of RO permeate is supplied for boiler makeup at two central utility plants. Reclaimed water will exceed State of Georgia Reclaimed Water Quality Standards as outlined in the Georgia Department of Natural Resources’ Guidelines for Water Reclamation and Urban Water Reuse.